Manufacturing

With our custom manufacturing capabilities, we can develop unique parts for your products—giving them a tailored design that adds value to your organization.

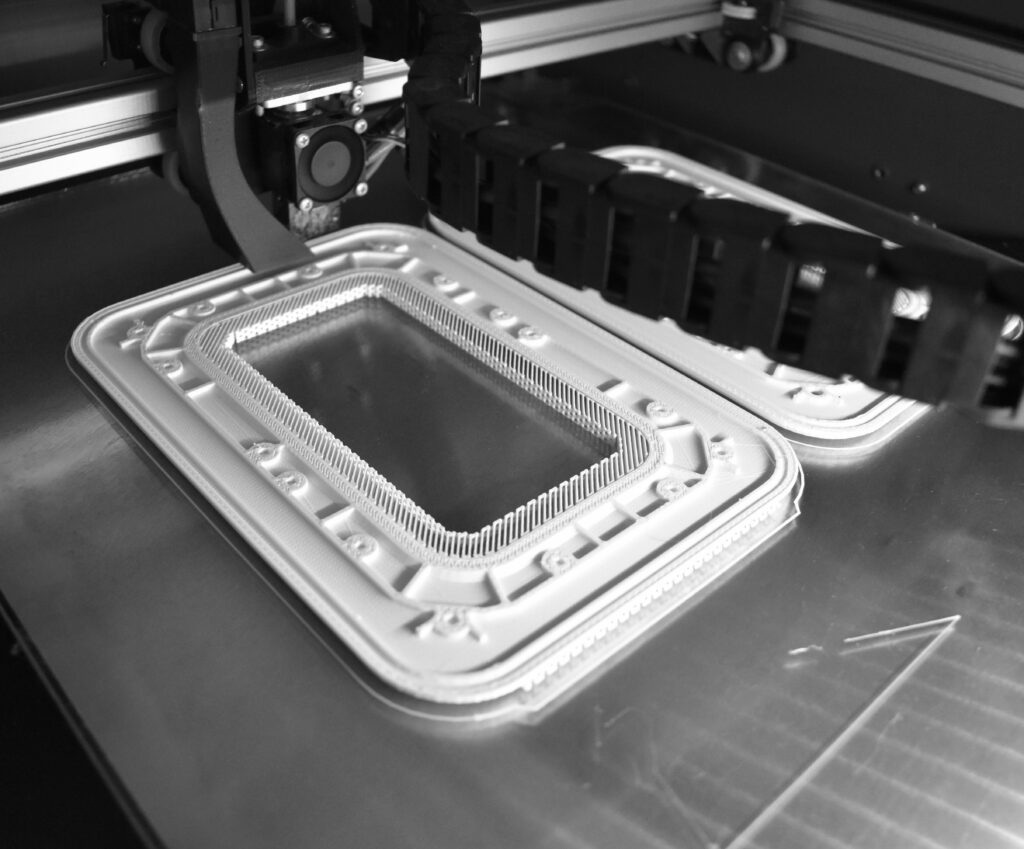

Rapid Prototypes

Our team provides expert assistance in the design phase with Auto CAD engineering and ASTM standard tests that allow you to approve materials and designs before production begins. Design changes can be made inexpensively and quickly in the prototyping phase.

Thermoforming

We use thermoforming processes to create and maintain an extensive portfolio of decorative window inserts, including the industry’s latest shapes and designs. And we can develop new designs for minimal upfront cost.

Injection Molding

We combine injection molding technology with our stick welded capability to provide the most flexible and comprehensive window system offering in the industry.

Custom Extrusions

We use the latest plastic and EPDM extrusion techniques along with the highest performing materials to manufacture all types of custom extrusions specifically for the garage door market–so we can develop products that work for your specific application.

Materials

Need a one-stop solution to keeping your production goals on track?

Action OEM is part of the Action Industries family.

Need a partner that knows parts? We’re a full-service resource that focuses exclusively on the garage door market.

Learn More